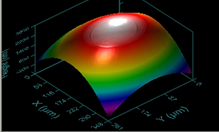

Undoubtedly, the polishing process is the most important manufacturing stage, as it not only provides proper shape geometry and smoothness of the ferrule’s end face but it also guarantees first-rate parameters. As a result, such parameters ensure low IL and maintain RL at the desirable level. Is it really worth buying a connector from a supplier who does not have necessary equipment to verify these parameters? At the end, our network will pay the price for neglecting this decision. What are the disadvantages involved in the use connectors with the wrong geometry of how these parameters affect the change in value of attenuation and return loss as well as climatic stability optical connectors?

We invite you to familiarize yourself with our next technical article, which was dedicated to topics related to the correct geometry of the connector's ferrule and influence of geometrical parameters on the quality of optical connection.

The article is available for download in the Downloads section.